Simplify Truck Scale Projects

Engineering, procurement and construction firms encounter a variety of challenges when taking on a truck scale project, such as managing complex projects with numerous stakeholders, ensuring regulatory compliance and mitigating risks related to cost and schedule overruns. Additionally, they must adapt to the constantly evolving landscape of technology, innovation and sustainability to stay competitive in the marketplace. With infrastructure funding ramping up projects nationwide, it is more critical than ever for EPCs to understand all of the components associated with truck scale projects.

Truck Scale Projects

A truck scale consists of multiple components that work together to measure a vehicle’s weight. These components can include:

- Ramps–used to bring the truck to the same level as the scale

- Gates–programmed to open and close at specific points during the weighing process to guide drivers

- Approaches–allow trucks to enter the scale from a level surface to ensure accuracy

- Scalehouse–houses the scale indicator and operator if applicable

- Indicators–serve as the control panel for the scale

- Computers–house the scale software, automating data capture, speeding up transactions and reducing opportunities for error

- Printers–used for printing transaction tickets

- Weighbridge–serves as the driving surface for trucks

- Junction box–serves as a connection point for the load cells

- Load cells–measure the weight on the scale

- Load-cell cables–transmits the load cell signal to the indicator

- Unattended kiosk–enables drivers to process their own weighing transactions without the need for a scalehouse operator

- Traffic control solutions–streamline flow and provide driver instruction

- Remote weight displays–displays the truck’s weight to the driver

The scope of a truck scale project can be intimidating when you realize it involves more than just the weighbridge itself. METTLER TOLEDO is a full-solution provider, meaning that it can provide everything you would need for a truck scale project.

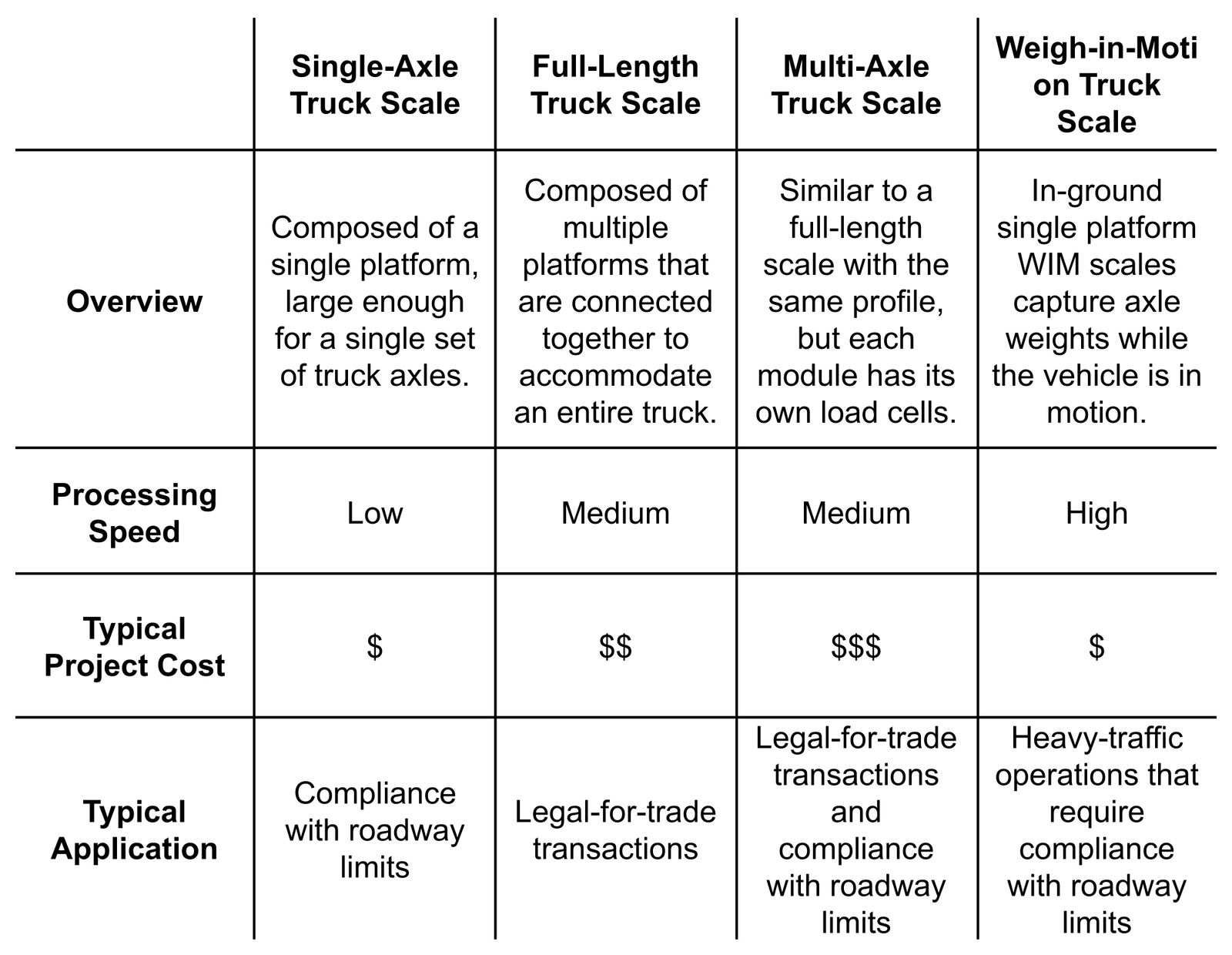

Explore below the different types of truck scales and the benefits of each.

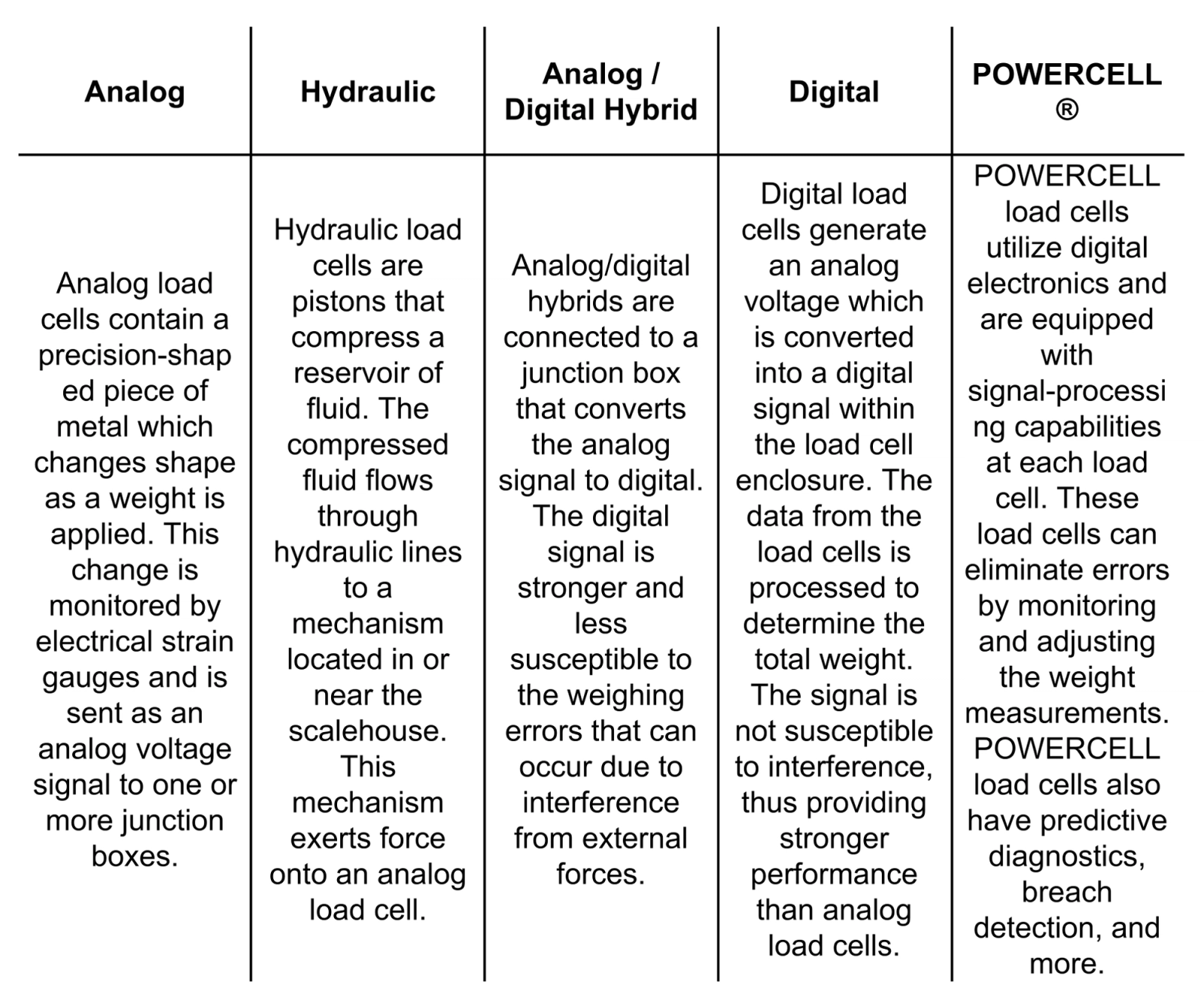

Load Cells

Load cells are the sensors that actually measure the weight of the truck pulling onto the scale. There are many types of load cells, all of which vary greatly in accuracy, reliability, environmental protection and more.

Explore below the different types of load cells and the benefits of each.

POWERCELL® PDX® smart digital load cells offer premium accuracy and reliability, protecting your customers’ operations from lightning, flooding, extreme temperatures and more

Watch the video to learn more.

METTLER TOLEDO has a wide range of experience working with EPCs around the world on vehicle scale projects. Our expertise helps to simplify your job–from finding the right solution for your customer, delivering the right documentation when you need it, all the way through installation and training.

To learn more about METTLER TOLEDO’s vehicle scale offerings, download the free Truck Scale Project Guide or the Infrastructure Law Guide to learn more.

Related stories

Keep Your Fleet Safety Plans Simple and Accessible

Building Supply Distributors: Taking Control of Jobsite Delivery in Uncertain Times