Ground protection mats have the power to preserve uptime, reduce equipment damage and minimize risks. With multiple current realities eroding construction profits and shrinking timelines, construction leaders must leverage every opportunity to maximize performance and reduce risk in the field. Ground protection matting is one of those opportunities.

Installing the right mats in the right places across the jobsite can help preserve uptime in wet or muddy conditions. It can protect equipment from damage, reduce impacts on wetlands and other ecologically sensitive habitats, and improve worker safety.

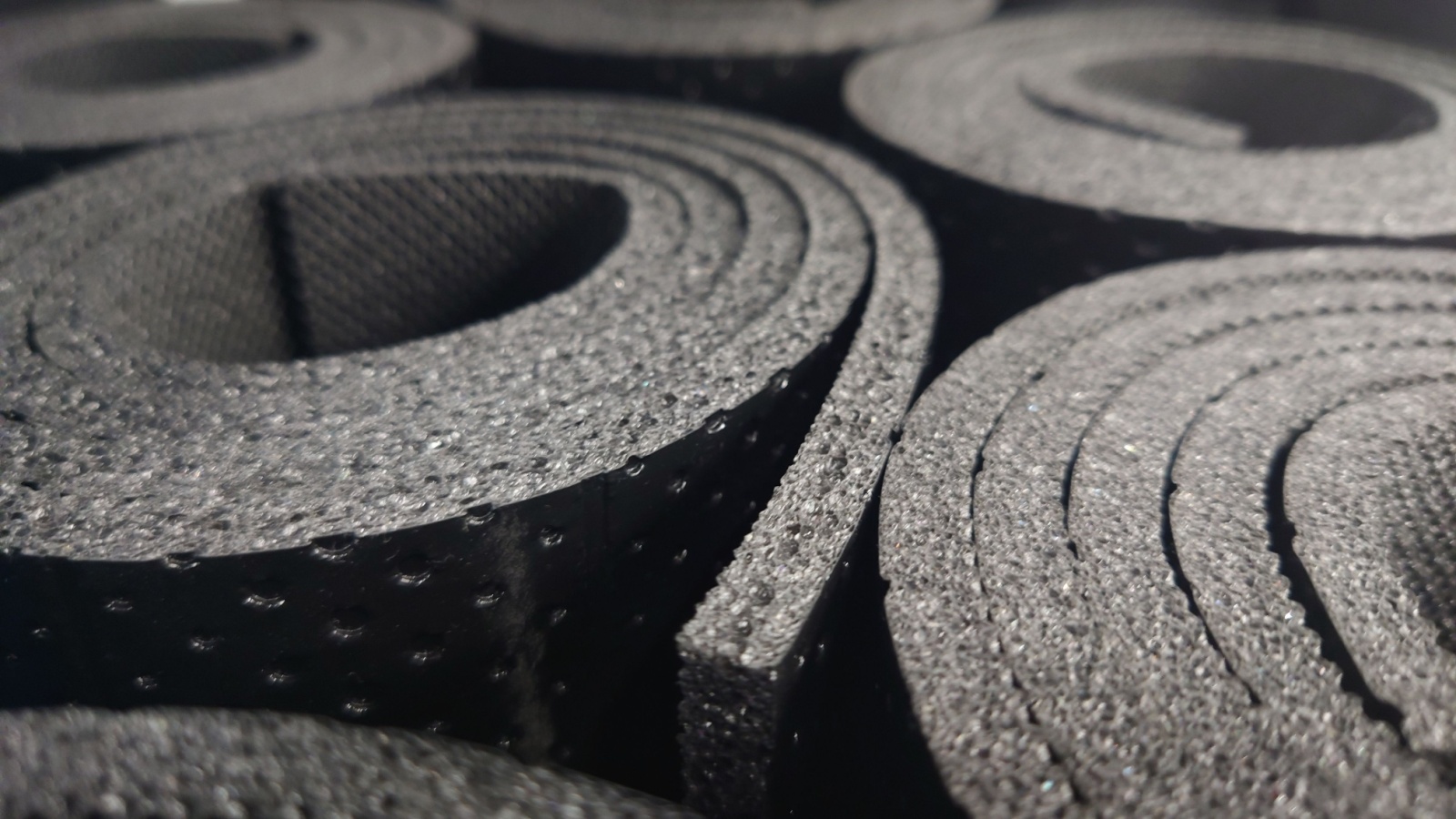

Ground protection mats include hardwood timber mats, cross-laminated timber mats, composite mats made from high-density polyethylene plastic, heavy-duty crane mats and trackout control mats. Mats can be quickly repositioned as the project progresses.

Before writing off ground protection mats as an unnecessary expense, managers should understand the return on investment they offer.

Minimizing Downtime

Inclement weather disrupts 45% of construction projects nationwide. Muddy conditions resulting from rain, snow or spring melts often cause costly work stoppages as crews wait for the ground to dry out.

Mats preserve uptime by providing smooth, level, stable surfaces that allow crews and equipment to move around the site safely and efficiently. Timber mats create a raised surface, which allows for water runoff underneath and reduces water pooling. Some have coated ends for protection against rot.

Contractors who utilize ground protection mats often save more than the cost of the mats in days of downtime avoided. The increased operational resilience mats provide helps protect project timelines and, in turn, profitability.

An added productivity bonus of installing ground protection mats around the jobsite, including parking pads and staging areas: Subcontractors who are spread thin across multiple projects are more likely to prioritize work on jobsites that are clean and mud-free.

Protecting Equipment and Materials

Heavy equipment is a significant capital investment. Mats allow equipment operators to maneuver safely regardless of the ground conditions. They prevent machines from getting stuck in soft soil or hitting large rocks that could damage tires and undercarriages. They also reduce wear on equipment.

Mats installed under stationary assets such as pumps and generators keep those assets dry and out of mud and water, which helps prevent unexpected failures. Placing mats under pumps protects against another not-uncommon scenario: pumps sliding down a muddy slope into the body of water below.

Contractors who use mats to create smooth surfaces for staging areas protect their high-value materials from mud and moisture.

Improving Jobsite Safety

Safety is an executive-level concern, especially given the many business impacts of safety incidents. Ground protection mats reduce risk across the jobsite. For example, by providing stable, level surfaces for heavy equipment, mats help prevent equipment from tilting and tipping over.

Walkways made of mats increase traction for workers on foot and protect against trips, falls and turned ankles caused by muddy ground and ruts left by dried mud. Installing mats around restrooms and office trailers limits the amount of mud tracked in, minimizing slip hazards.

Crane mats increase the safety of crane operations, which pose significant danger. Timber crane mats, often paired with timber outrigger mats, are thick, heavy-duty mats designed to support the extreme weight of cranes and their loads without shifting or buckling. Properly constructed and deployed, crane mats mitigate the risk of a catastrophic crane tip-over, safeguarding personnel, equipment and the company’s hard-earned safety record.

Supporting Sustainability Efforts

Ground protection mats limit the environmental impact of operations, especially in sensitive environments.

Mats used to create temporary roadways and equipment platforms minimize soil compaction by distributing the downward pressure of wheels, tracks and outriggers. Similarly, mats placed under restroom trailers, mobile offices and storage containers reduce soil compaction by evenly distributing the weight of these units.

Reducing soil compaction helps limit stormwater runoff, supporting compliance with Stormwater Pollution Prevention Plans and reducing the financial risk of noncompliance. Mats also help preserve any vegetation beneath.

At project closeout, wood mats can be reused or recycled. Composite mats, which have lifespans of up to 10 years, are biodegradable and recyclable.

Limiting Jobsite Maintenance and Restoration

When mats instead of gravel are utilized to create temporary roads, parking pads and staging area surfaces, the need to maintain gravel is eliminated. Unlike gravel, mats don’t need to be raked and they aren’t eroded by weather.

Mats also help contractors keep the jobsite cleaner. Trackout mats placed at jobsite entrances remove excess dirt and debris from tires and tracks so they aren’t spread around the site. Walkways installed around office trailers, portable restrooms and storage containers decrease the amount of mud tracked inside these units, which minimizes the need for cleaning.

By reducing soil compaction and protecting vegetation, mats can significantly reduce the scope of site restoration work, and the associated costs, on projects that require contractors to return the site to its original condition at project completion.

Limiting Liability

Trackout control mats placed at jobsite exits dislodge debris such as rocks that could be carried onto the roadway and kicked up by vehicles. Should rocks cause damage to vehicles, including windshields, contractors may be liable for the damage.

These mats can be installed over dirt, asphalt, turf, sand and grass surfaces. They help ensure compliance with local jurisdiction or Department of Transportation regulations that require project owners to implement measures to prevent construction debris from being carried onto roadways. They also reduce the need to deploy street sweepers near jobsite exits.

Planning in Advance for Ground Protection Mats

Mats are not a one-size-fits-all solution. The best type of mat depends on factors such as the type of environment, the ground conditions, the weight and type of equipment in use, the project duration and the project budget.

A matting provider that carries an extensive inventory of mats of different types will advise on the best mats for the jobsite and application. They can also forecast the number of mats needed based on historical data to help ensure availability. A full-service, turnkey provider will install the mats to create temporary roads, work surfaces and trackout areas. Some even perform site restoration.

SEE ALSO: KEEP YOUR FLEET SAFETY PLANS SIMPLE AND ACCESSIBLE