What began as an idea in a dorm room is now revolutionizing the face of safety in the construction industry. Some employees—not exclusive to the construction industry—fear robots and AI taking over their jobs, but others are more than happy to hand them over, especially when their safety is on the line—or up against the wall in the case of Gecko Robotics.

In 2013, Gecko co-founder and CEO Jake Loosararian was an electrical engineering major in college when he received an internship with and took a tour of a power manufacturing facility in Northwestern Pennsylvania. “From there,” he says, “I was able to understand how the facility works, but most importantly I got to see a lot of the critical infrastructure that makes power plants go.” This power plant, however, was out of commission for nearly half the year due to pressure tube explosions inside of the boiler.

When a boiler breaks, someone has to fix it, and that can be dangerous—even deadly. “The only way to stop the boiler tubes from exploding was to send a person through a little manhole into a football-field sized room,” says Loosararian. This room is not only enormously large, but enormously deep, and to get the boiler up and running again—or prevent future downtime—it is someone’s job to scale the 200-foot walls and manually inspect for damage. “It’s an impossible job,” says Loosararian. “The plant manager I was touring with said these errors lose the company around $40 to $50 million each year. In fact, someone had actually died during that evaluation the year before. So that was a story that stuck with me.”

That experience was so stuck with Loosararian that it led him to pursue one solution to several problems: identifying aging infrastructure, protecting a company’s workforce and shoring up one of many holes leading to the industry’s broader workforce shortage. Loosararian then spent the rest of his college career prototyping a robot that could climb vertical structures while simultaneously creating datasets about the health of those structures. When he officially co-founded his company, Gecko Robotics, in 2013 with Troy Demmer, he says, “We bootstrapped it for three years. By 2016, I was down to a hundred bucks in my bank account. There are only a few founders who are crazy enough to start a hardware company because they’re very difficult and they fail most often. But fundamentally, we needed to collect the data so that we could help customers understand the different actions to take for their companies.”

Wall-scaling robots serve so many companies and climb so many types of infrastructure—from dams to bridges, tanks to pipelines, boilers and beyond—replacing manual, analog, dangerous means of collecting, storing and sharing data, and replacing the people who would have been doing that work. “We call them Joe-on-a-Rope,” says Loosararian, a literal term for personnel designated to inspect aging infrastructure and gather data by hand. During this manual process, Loosararian found that not only are companies losing capital directly from their infrastructure—whether it break down and need repair or is being replaced before it actually needs to be—but from their increasing insurance premiums when putting employees in these dangerous positions.

That is where Loosararian and his army of Geckos come in and gather as much health data on a company’s critical assets to determine how and where to best deploy their capital. “We’re already seeing an extrapolated 20% reduction in capex spend and 3-4% net margin improvement,” he says, “combined with an increase in useful life of those infrastructure.”

Bottom line: Robots are cool. They can scale walls, protect people and predict the future of the built world by gathering information—which is the real asset, and sometimes harder to manufacture than the robots themselves. “Robots are only a means to get information and datasets that are impossible to get anywhere else,” says Loosararian. “The software is really the hard thing. We have more software engineers here than robotics experts.”

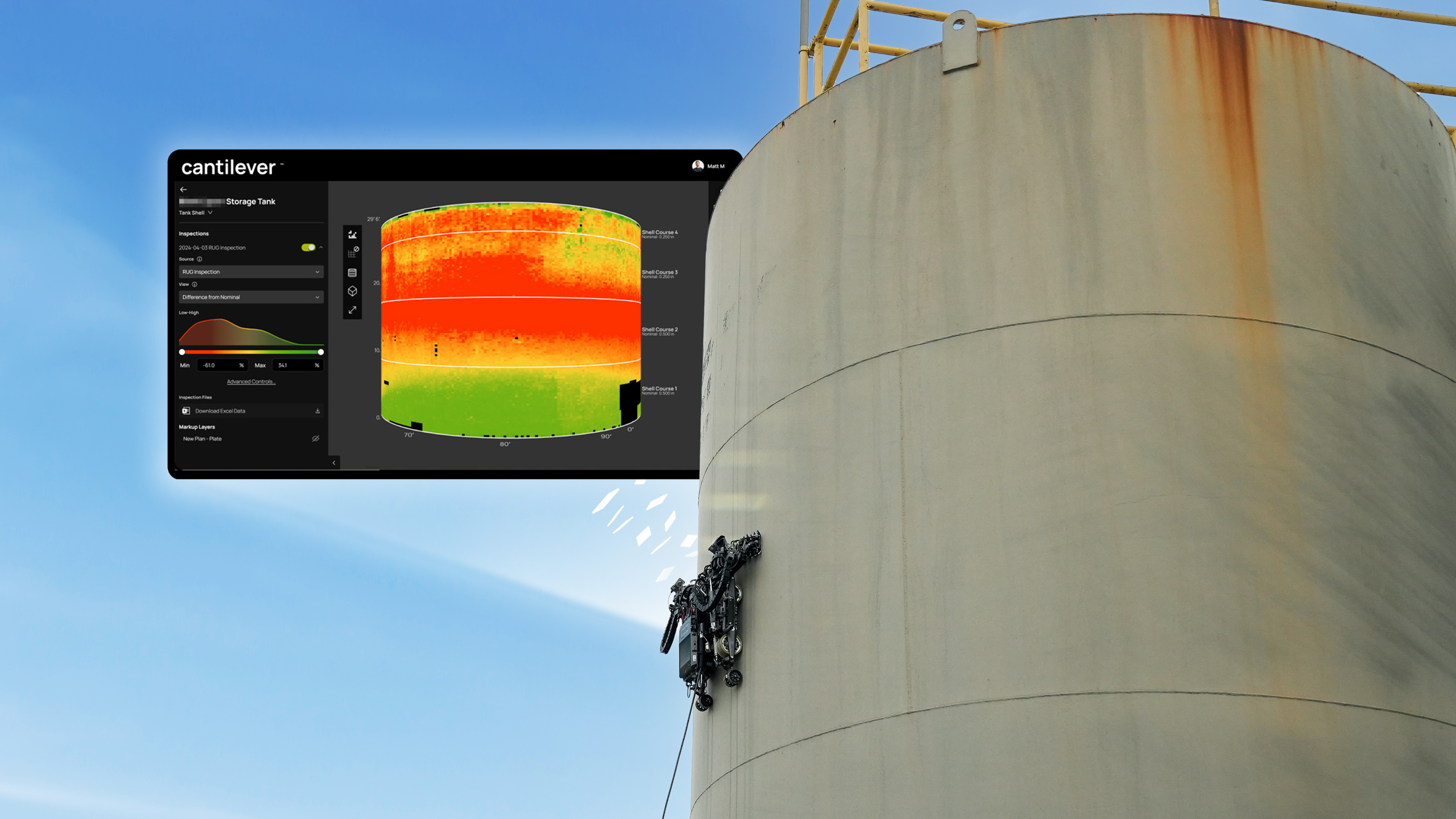

Today, any construction company investing in new hardware will tell you it is imperative to simultaneously invest in compatible software to operate and manage that hardware. Loosararian cuts out the technological middleman by providing that software alongside his robots. After launching his SaaS, Cantilever, earlier this year, Loosararian has actually seen an increase in interest in his robots as well.

Construction companies adopting various forms of construction technology today will say you cannot invest in one form alone. Many products are a package deal. Loosararian says, “You buy into the software and the robot suite packages, and they continue to get better and better because of the pace of development.” And as that tech gets better, so too will the companies using it. Loosararian also learns from the companies using his contech package how better to develop his products—so it’s a continuous cycle of improvement for all parties. “Typically,” he says, “the question that we get asked is, ‘Can I put this into Cantilever?’ Which is a great indicator of how customers that are actually running these facilities and thinking about the software and its utility.”

As contech sets companies apart from the pack regarding equipment efficiency and productivity, it will also set those companies apart regarding workforce. “Technology does produce the goods as it relates to business results, but it also produces the goods as it relates to the interests of drawing the best talent in the world to it,” says Loosararian.

After recruiting that talent, cutting-edge robots and SaaS technology then help to retain it by circling back to the very reason Loosararian founded Gecko in the first place: keeping that talent safe. Following the initial 60-day workup, companies can continue their infrastructure health evaluations with Gecko every six to 12 months, for however many years they choose.

Loosararian says then, “Customers will deploy drones, robot dogs, fixed sensors, submersibles, all the different kinds of technologies that can be incorporated into Cantilever.” This blend of hardware, software and innovation allows for companies to evolve over time—ensuring improvement of their products, maintenance of their infrastructure and retention of their workforce.

Loosararian says, “Every time I’m at a facility there are crowds of people wanting to take pictures with the robots, saying, ‘I’m going to show my kids, they’re going to be so excited about this.’ There is such an excitement around new technology and being a part of something that feels cutting edge and giving someone a tool while also saying, ‘You don’t have to put yourself in harm’s way.’ The robot will do that and it will do it while gathering information about equipment that ensures security and safety for those working on it.”