The potential applications of machine learning and artificial intelligence (AI) in construction are vast, and for early adopters, these technologies are already helping to make jobsites safer, more efficient and more productive. Requests for information, open issues and change orders are standard in the construction industry. Machine learning is like a smart assistant that can scrutinize this mountain of data, learn from it and then alert project managers about the critical items that need their attention.

This type of AI is also being used to track the real-time interactions of workers, machinery and objects on the jobsite and alert supervisors of potential safety issues, construction errors and productivity issues.

What are some of the top benefits of using AI and machine learning in the construction industry?

Expedited Project Delivery

Even the best-planned projects can run over budget. AI can help predict cost overruns based on factors such as project size, contract type and the expertise of project managers. Historical data like planned start and end dates are used by predictive models to envision realistic timelines for future projects. In addition, a robot can constantly evaluate job progress and the location of workers and equipment so that project managers can know instantly which jobsites have enough workers and equipment to complete the project on schedule, and which might be falling behind.

Better Building Design

Building Information Modeling gives architecture, engineering and construction professionals insights to efficiently plan, design, construct and manage buildings and infrastructure. In order to plan and design the construction of a building, 3D BIM models need to take into consideration the architecture, engineering, mechanical, electrical and plumbing (MEP) plans and the sequence of activities of the respective teams. The challenge is to ensure that the different models from the sub-teams do not clash with each other. Today, the construction industry is using machine learning in the form of generative design to identify and mitigate clashes between the different models generated by the different teams in the planning and design phase to prevent rework. As the software learns from each iteration, it can come up with optimal solutions for future projects as well.

Increased Risk Mitigation and Safety

According to the Occupational Safety and Health Administration, one in five worker deaths last year were in construction and the leading causes of private sector worker deaths (excluding highway collisions) in the construction industry were falls, followed by struck by object, electrocution and caught-in/between. Every construction project has some risk; usually the larger the project, the more risk, as there are multiple subcontractors working on different trades in parallel on the jobsite. Today, general contractors use AI and machine learning solutions to monitor and prioritize risk on the jobsite and automatically assign priority to more significant safety issues. This allows the project team to focus their limited time and resources on the biggest risk factors.

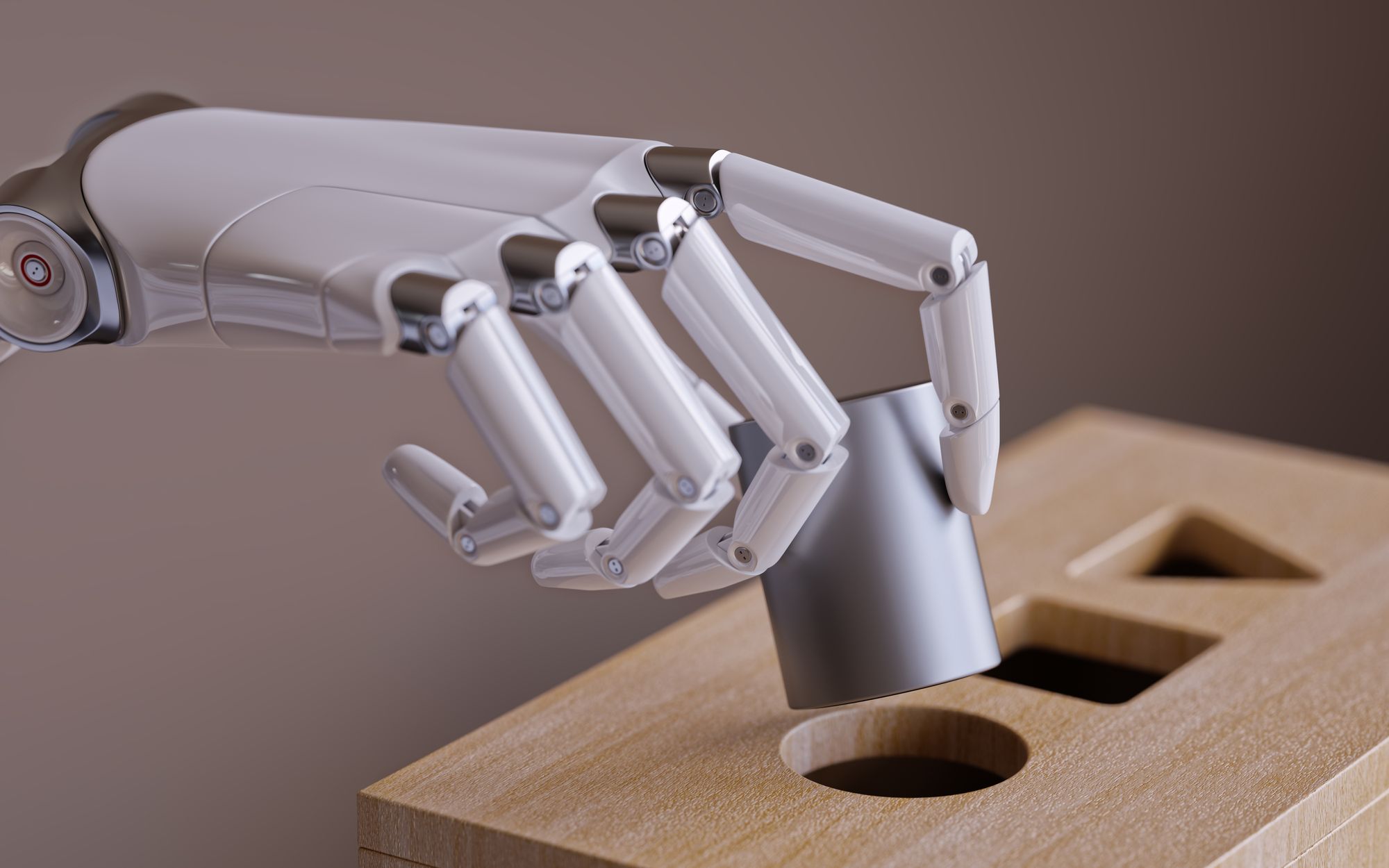

Automated Offsite Construction

Construction companies are increasingly relying on offsite factories staffed by autonomous robots that piece together components of a building, which are then pieced together by human workers onsite. Structures like walls can be completed assembly-line style by autonomous machines more efficiently than their human counterparts, leaving human workers to finish the detail work like plumbing, HVAC and electrical systems when the structure is fitted together.

More Productive JobSites

Construction companies are using AI and machine learning to better plan for distribution of labor and machinery across jobs. Companies are also starting to offer self-driving construction machinery to perform repetitive tasks more efficiently than their human counterparts, such as pouring concrete, bricklaying, welding and demolition. This frees up human workers for the construction work itself and reduces the overall time required to complete the project.

While experts expect construction technology to become more intelligent and autonomous with new AI techniques, construction executives should prioritize their investment in AI based on areas where it can have the most impact on their company’s unique needs.