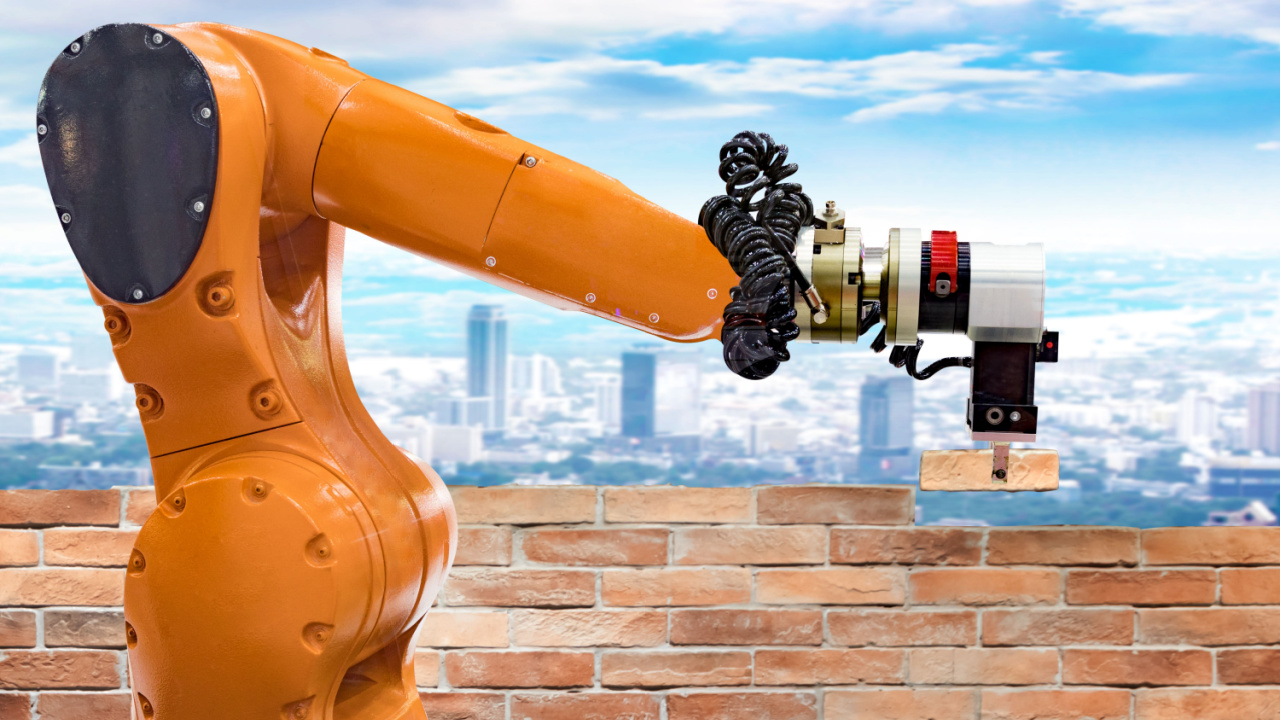

2024 Is the Year for Autonomous Robots in Construction

Over the past decade, there has been significant growth in the use of autonomous and robotics solutions in the construction industry. What used to be seen as a futuristic dream is now offering significant real-world benefits that are transforming traditional workflows.

Robotics, task and machine automation and other emerging technologies are helping improve jobsite productivity and efficiency by performing repetitive tasks that can be monotonous, dangerous, dirty and time consuming. The adoption of autonomous solutions presents a competitive advantage for contractors who are looking to improve productivity and efficiency, as well as reduce costs, address the skilled labor shortage and ensure worker safety.

INTELLIGENT TECHNOLOGY WITH A BIG IMPACT

In addition to delivering benefits in the field, these solutions are adding value through data collection and analysis that can be used for predictive insights and lead to incremental productivity gains. The better these autonomous and robotic technologies become, the better visibility companies have into their daily operations, and the data collected over time can help them make better-informed decisions.

Another benefit of this type of technology is that as older generations retire and younger generations opt for other career paths, autonomous robots can help alleviate some of the challenges caused by the current skilled-labor shortage. Robots can also be used to help train new workers, introducing autonomy incrementally and slowly increasing the capabilities of the machine, thereby upskilling the operator.

Autonomous robots and machines can also be used to perform more dangerous tasks or work in hazardous environments, reducing the risk of injuries and accidents. Remote operation centers, where operators control autonomous machines from a central location, improve site safety by removing operators from dangerous environments, while maximizing equipment utilization and efficiency.

In addition to the operational benefits, autonomous machines and workflows deliver sustainability gains that benefit contractors, project owners and the environment. Introducing autonomous technology on a jobsite can deliver increased productivity and accuracy, less reliance on a depleted pool of qualified labor, consistent quality and can drastically reduce the amount of time, money and materials wasted due to rework. For example, autonomous machines can improve accuracy that minimizes overlap from compacting or grading. This reduces the total number of passes, so work is done faster, saving fuel and wear and tear on machines.

AUTONOMOUS ROBOTS IN ACTION

Autonomous robots are being deployed on today’s construction jobsites for a variety of purposes. When integrated with other technology, such as GNSS positioning or 3D scanning, they can move through a jobsite and streamline the process of tracking the status of the construction project on an ongoing basis. Let’s look at some of the ways these solutions are making a big impact.

Bid-to-Build Process

Autonomy is being used in the bid-to-build process to provide better visibility into daily operations. With small margins, construction business owners are focused on where they can make incremental gains. With autonomous machines, this progression can move from operator assist all the way through to gaining back-office visibility into what is happening day-to-day to make more informed decisions.

Advanced Path Planning

Advanced path planning technology offers automated, full path coverage and complete project trajectory from entry to exit, including logistics points. It leverages autonomous routing to keep machines moving for maximum operational efficiency and allows plans to be created in the office and adjustments to be made dynamically on the jobsite. This also helps maintain a safe working environment while maximizing utilization.

Hands-Free Steering Control

Horizontal steering control functionality automatically controls machines, such as dozers or soil compactors, to follow any horizontal alignment from the 3D model. This allows the operator to focus on grade, machine productivity and safety rather than worrying about steering. It also helps with sustainability as evidenced by a recent Trimble study that compared the results of manual operation to the use of assisted steering functionality and found that it reduced fuel consumption by more than 26% and had a potential carbon savings of 15,262 pounds.

Field Data Capture and Project Progress Tracking

When integrated with precise positioning and 3D scanning technology, robotic solutions can move through a jobsite and track the status of the project on an ongoing basis. This automated and repeatable approach to field data capture can provide contractors with real-time awareness of the construction status, helping to accelerate project delivery.

When it comes to autonomous robots in construction, the future is now. From automating specific tasks like machine steering, to scanning project progress in hazardous work environments, contractors around the world are integrating robots and other autonomous solutions into their construction workflows. This is giving teams the ability to assign their valuable skilled workers to more complex tasks, while also utilizing data to make more informed decisions that lower overall risk, improve production and quality, and enhance jobsite safety.

Robots and other autonomous technologies are an important part of the future of construction, helping solve progressively more complex problems and enabling higher value along the way.

Related stories