Winning Strategies for Virtual Design and Construction Success

Eliminate Waste, Improve Safety and Increase Productivity

Ask anyone in the construction industry if they believe any two projects are ever the same, the answer is “no.” But while details and specs are nuanced and differ from project to project, planning and execution on the macro level can be far simpler.

Safety, quality and productivity lay the foundation for a great virtual design and construction (VDC) strategy, and are of the utmost importance for the self-perform team at Barton Malow.

Seeing the Plan: Plan the work, Work the plan

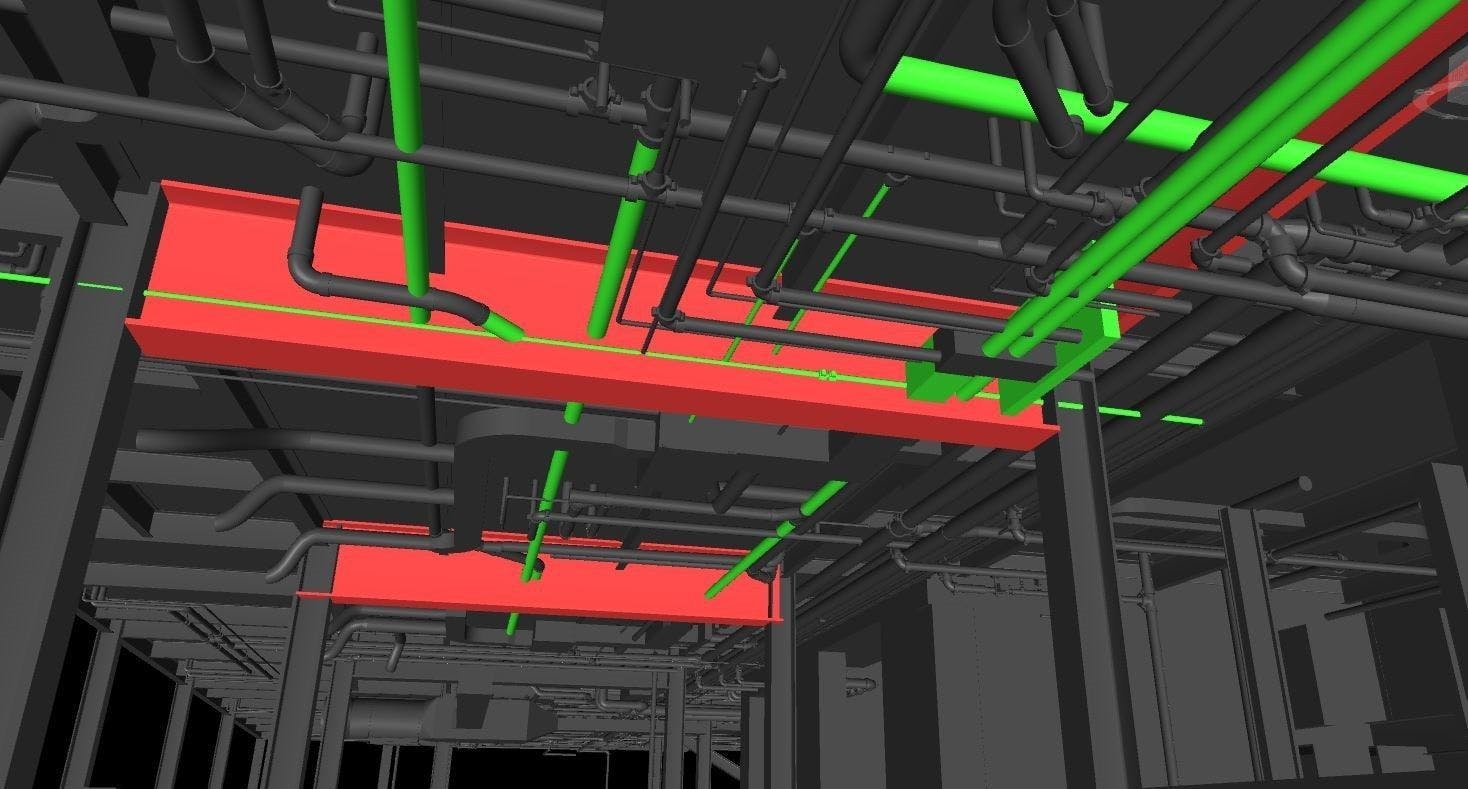

At every project exists the opportunity to utilize technology and apply the three integral parts of a VDC strategy. Before building even begins, one must be able to visualize how something will be built. Optimizing performance begins with harnessing the power of BIM to create in-depth visuals (3-D, 4-D, 5-D, 6-D) through tools such as Tekla, SketchUp, Revit and Maya, which give teams a proper visual to work with. Depending on depth, these models not only showcase geometry, but can also detail how much rebar, concrete formwork, structural steel etc., will be needed and where.

This is vital in a field like construction, where multiple teams are working alongside each other completed different tasks in search of a common goal.

Coordination: New Tool, Same Concept

Coordination is not a new concept in the industry, but there are tools to make it more effective. Depending on the complexity of a project, there could be dozens of teams on any given jobsite. A proper VDC strategy is built on communication and coordination. Why is this important? With trade, electrical, plumbing and so many other teams all present during a project, creating an environment where each step is coordinated between the parties provides the best possible outcome.

Only through a detailed plan that starts with visualization are construction companies able to execute a plan thoroughly, eliminate hurdles and minimize adjustments in the field—all of which can create waste and increase safety hazards, if not checked.

Making the Time: Utilizing Time Wisely

Just because one’s visualizations are ready and coordination is at the forefront doesn’t mean the trouble is over, though. One of the largest challenges on the field is fitting all trade work within a small window of time.

How can one navigate that obstacle? Start earlier. Modeling during the pre-construction efforts allows estimators to focus on the job, units and personnel by ensuring quantity takeoff is not necessary. These initial efforts are meant to create a system where each individual is responsible for their area of expertise. Estimators will estimate, modelers will model, and builders will build.

Best Practice: Technology-enabled

Creating a synergy between BIM and self-perform is the focal point of a successful project. Everything virtual one could do on the field. It’s vital to provide the people with boots on the ground with the technological tools they need to do their job. It doesn’t do any construction company good if there’s technology in the office but not in the field.

Implementing new technology and ensuring that one’s workforce is given the tools and education to succeed is a time-consuming investment, and it requires a bit of patience. But the payoff is a team that’s built to innovate in a construction industry that is ripe for change.

Finally, the best way to ensure a seamless start-to-finish requires something more than just technology or building prowess: commitment and confidence. Commitment to innovative new technologies and coupling it with the confidence to execute on-field could mean the difference between having a technology-enabled workforce or not. Through a proper VDC strategy, construction companies lead from the front—not behind.

Related stories